Blocks for Lifting & Rigging: ASME B30

Whether you are lifting or rigging, the block you choose is one of the most important decisions you will make. Your gear is the difference between a job well done and an accident with unforeseen consequences. Our dedicated Gear Experts® have spent years sourcing the best, and most reliable equipment to help you get the job done safely. This week we are focusing on blocks and the ASME B30 standard.

Whether you are lifting or rigging, the block you choose is one of the most important decisions you will make. Your gear is the difference between a job well done and an accident with unforeseen consequences. Our dedicated Gear Experts® have spent years sourcing the best, and most reliable equipment to help you get the job done safely. This week we are focusing on blocks and the ASME B30 standard.

Materials

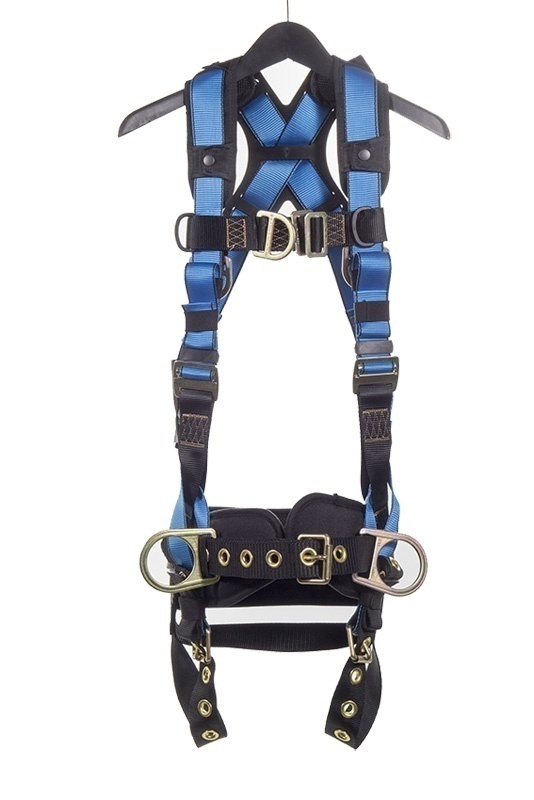

The rigging block should be able to permanently deform before losing the ability to support the load. This ensures that you should notice the block has been overloaded before it fails. We will cover inspection shortly, but remember that proper inspection is extremely important. The side plates should be made of metal, wood, or a synthetic material. Obviously, you’ll almost always see steel or aluminum blocks in the tower industry. The sheaves and load-bearing straps or fittings should be made of metal as well.

Rated Loads

Load weight should always be kept within the recommended limits of the manufacturer. It is also important to remember that this limit is the maximum load applied, not a single load line. What this means is that if the block is rigged at the top of the tower and you’re lifting something that weighs 1,000 pounds, there could be up to 2,000 pounds of total weight on the block. These concepts can get pretty complicated and are outside of the range of a blog post. For more information, check out a competent rigger training course.

Proper IdentificationÂ

ASME B30 26-5.5 covers proper identification. Each block has to have markings providing the manufacturer, rated load, and acceptable rope sizes. The block should also be maintained by the user to ensure these markings remain legible through the life of the hardware.

ASME B30 26-5.5 covers proper identification. Each block has to have markings providing the manufacturer, rated load, and acceptable rope sizes. The block should also be maintained by the user to ensure these markings remain legible through the life of the hardware.

Inspection, Repair, and Removal

A qualified person should designate whether the hardware is suitable for rigging, and remove it from service if it’s not. Prior to use, all blocks should be inspected to verify compliance with ASME B30. A visual inspection should be performed each time the block is used. Permanently installed rigging hardware should have periodic inspections as well. Written records are not required for these inspections, but remember, if it doesn’t pass inspection you must remove it from service. Written records may not be required, but they are recommended. It makes it much easier to track inspection and keep everyone safe while on the job. If a block shows any of the following during inspection, they cannot be used in the field and should be replaced.

- Missing or illegible identification

- Misalignment or wobble in sheaves

- Excessive sheave groove corrugation or wear

- Loose or missing nuts, bolts, cotter pins, snap rings, or other fasteners or retaining devices.

- Indications of heat damage or arc strikes

- Excessive pitting or corrosion

- Bent, cracked, twisted, distorted, or broken load-bearing components

- Excessive wear, nicks, or gouges

- 10% reduction of the original dimensions at any point on the device

- Excessive damage to load-bearing threads

- Evidence of unauthorized welding or modifications

- For hooks and shackles, removal criteria specified in those B30 standards

- Any other condition including visible damage that causes any doubt as to the integrity of the block.

Operating Practices

Obviously, load ratings should not be exceeded. Make sure you’re keeping clear of the block, its running lines, load, or any other part of the system during lifting. This includes walking or standing under a suspended load or lifting line. Also, don’t stand next to a rig when the line is under tension. As for rigging practices, avoid sharp angles or edges that could damage the block. And be sure not to drag blocks along abrasive surfaces. The load applied to the block should be in-line with the sheave to prevent side loading. Blocks with swivels help to avoid these problems.  Also, make sure your rope is securely in the groove of the sheave. Shock loading should also be avoided. This is not a comprehensive training. Before doing any lifting and rigging a competent rigger course should be completed. We also have a full line of training courses that are available for a range of different subjects. Those can be found here. Need help? Click here to contact a Gear Expert® and as always, Climb Higher®!

Social Tags

Be sure to follow us on social media to keep up with everything GME Supply has coming up in 2018. It will be exciting - we promise!

Facebook | Instagram | Youtube | Twitter | LinkedIn | Google+

Synthetic Rope Blocks

Rope blocks that are specially labeled for synthetic rope are hard to find, but your search ends here! We have just the block you need if you are looking for a synthetic rope block. Find out more information with this YouTube video!