YOU HAVE NO ITEMS IN YOUR CART.

Featured Brands

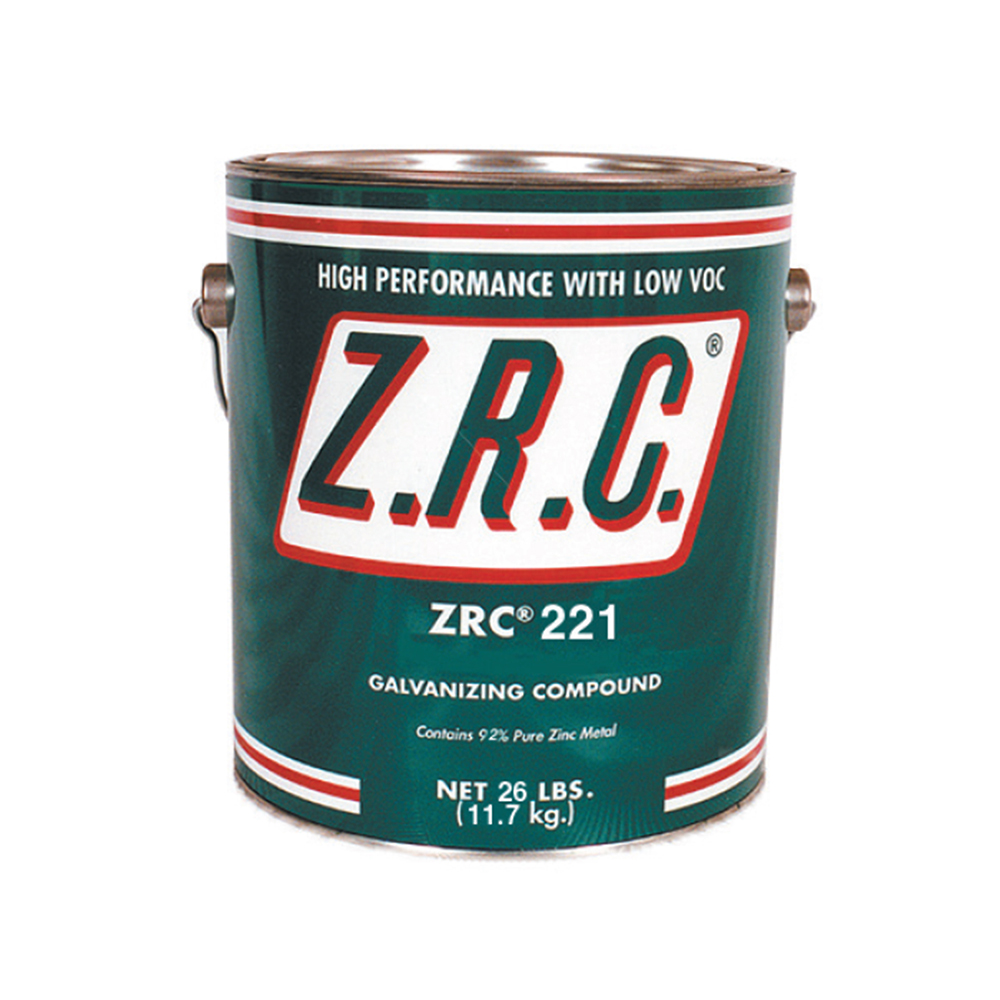

Model#: 50003

Stock#: ZR-50003

ZRC 221 Low VOC Cold Galvanizing Compound - 1 Gallon

$703.99

Get it by Apr 24

Get it by Apr 24

- 40% lower levels of volatile organic compounds than traditional cold galv

- Excellent for use in VOC-restricted areas

- Unlike hot-dip galvanizing, ZRC 221 is portable, flexible protection that can be applied in a variety of formats.

ZRC 221 Low VOC Cold Galvanizing Compound - 1 Gallon

The ZRC 221 Low VOC Cold Galvanizing Compound is the newest innovation in zinc-rich technology. It offers the same superior performance of traditional cold galv with 40% lower levels of volatile organic compounds — a more environmentally friendly protection option.

With its unique formulation, ??ZRC 221 Cold Galvanizing Compound is excellent for use in VOC-restricted areas. ZRC-221 may be used without a top coat in place of hot-dip galvanizing. Also used as a high-performance base coat with a variety of topcoats. Its specially formulated for:

- Galvalumeand Zinc Metallizing: ZRC 221 can be used for Galvalume and zinc metalizing projects.

- Weldments Repair: Can be used to repair weldments.

- Inorganic Zinc Coatings Repair: ZRC is also effective for inorganic zinc coatings repair.

- Long-Term Protection: It’s proven to be effective long-term protection for: structural steel, water and waste facilities, power plants, transmission towers and antennae, steel decking and bridges, and numerous OEM uses.

- Hot-Dip Galvanizing Repair & Regalvanizing: It’s a flexible option for repair of worn hot-dip galvanized materials.

Features:

- 40% lower levels of volatile organic compounds than traditional cold galv

- Excellent for use in VOC-restricted areas

- Unlike hot-dip galvanizing, ZRC 221 is portable, flexible protection that can be applied in a variety of formats.

- Excellent for reducing VOC emissions in restricted areas/production facilities

- 92% zinc in the dry film using only Type III “ultra pure” ASTM-D-520 zinc

- ISO 9001 registration assures the highest quality consistently

- Meets and exceeds the performance requirements of Fed. Spec.

- DOD-P-21035A (Galvanizing Repair Spec); MIL-P-26915A (USAF Zinc Dust Primer); ASTM Des. A-780 (Standard Practice for Repair of Damaged Hot-Dip Galvanized Coatings); SSPC-Paint 20 (Specification for Zinc-Rich Primer)

- Passes 3,000 hours salt spray testing without failure (ASTM Des. B117)

- Passes Preece Test (ASTM Des. A239) for hot-dip galvanizing

Flexible Application Formats

Unlike hot-dip galvanizing, ZRC 221 is portable, flexible protection that can be applied in a variety of formats.

- Brush, Roller, and Aerosol: Apply as received in the container. For brush application, we recommend only 100% Natural Chinese Bristle brushes. For roller application, we recommend rollers with a 3/8” nap, made of mohair or lambs wool (sheepskin).

- Spray (Low Pressure Compressor): ZRC can also be applied as a spray.

- Atomized Air Pressure: 50 psi (1.3 kg/cm²)

- Fluid Pressure: 15 to 20 psi (0.4-0.6 kg/cm²)

- Orifice of Tip: 0.080 inches (0.20 cm)

- Viscosity Reduction: 5:1 ZRC-221 : parachloro-triflouromethyl-benzene (vol)

- Spray (Airless): Recommended Procedure: Connect hose directly to pump ensuring a hose length of 50 ft. max. Use the least pressure possible. Start at 1500 lbs. (680 kg) and increase as required for good spraying.

- Pump: 30:1 Ratio

- Hose: 1/2" (1.3 cm)(I.D.) Airless Type

- Orifice of Tip: 60° - .026 in. (0.07 cm)

- Type of Tip: Tungsten carbide, reversing

- Filter Screens: Complete removal is recommended. However, if screens are employed, use no less than 30 mesh.

- Viscosity: No reduction required

Specifications:

- SSPC Paint Specification 20 – Zinc-Rich Coating: Type II – Organic; Level 1 – equal to or greater than 92% zinc dust by weight present in the dried film

- Zinc Dust Content - ASTM D 520 Type III Zinc Dust — .002% maximum lead by weight

- VOC Content — ASTM D 3960, 221 g/l (3.3 lbs per gallon) maximum

Testing Data:

- Meets and exceeds the performance requirements of Fed. Spec. DOD-P-21035A, formerly MIL-P-21035 (Galvanizing Repair Spec.)

- Meets and exceeds the performance requirements of Fed. Spec. MIL-P-26915A (USAF Zinc Dust Primer)

- Passes 3,000 hours salt spray testing without failure** (ASTM Des. B117)

- Passes Preece Test (ASTM Des. A239) for hot-dip galvanizing

- Resists intermittent dry-heat temperatures up to 750°F

- Meets and exceeds ASTM Des. A-780 (Standard Practice for Repair of Damaged Hot-Dip Galvanized Coatings)

- Meets and exceeds SSPC-Paint 20 (Specification for Zinc-Rich Primer)

ZR-50003

| Color: | Battleship Grey |

| Manufacturer: | ZRC Worldwide |

| Weight: | 25.00 |

Reviews