YOU HAVE NO ITEMS IN YOUR CART.

Featured Brands

GME Supply Safety Stand-Down Week 2021: Inspection Time!

Day Three

The Importance of Safety Equipment Inspection

When working at heights, your fall protection and safety equipment is almost certainly the most important part of your work gear. You use the gear all day, everyday. That’s exactly why inspection is so critical. It takes just a few minutes to look over all of your equipment each day before you begin work. It ensures that even if you put it away in perfect condition last time you used it, that it wasn’t damaged in transit or storage. And, let’s not forget a rogue coworker who “just needed to borrow it for a minute” that could have damaged it without you knowing.

What Needs to Be Inspected?

Short answer? Basically everything.

That's A Lot of Inspections

Obviously there is a lot to go through everyday before you start work. Some people out there only take a piece of equipment out of service once it actually fails. That’s a terrible mindset to have when you’re thinking about the fall protection gear that you’re relying on to save your life in the event of a fall.

Every worker should always do a full check of all of their equipment before work begins each day. If you find anything wrong with the gear, if it does not pass the inspection, you should take it out of service. For this reason, an extra back up harness, lanyard, etc wouldn’t be a bad idea to have in the work trailer!

There are a number of resources out there to review proper inspection practices. Many of which our Gear Experts® have helped various manufacturers produce!

Free Resources

Free Inspection Forms

Inspecting Soft Goods

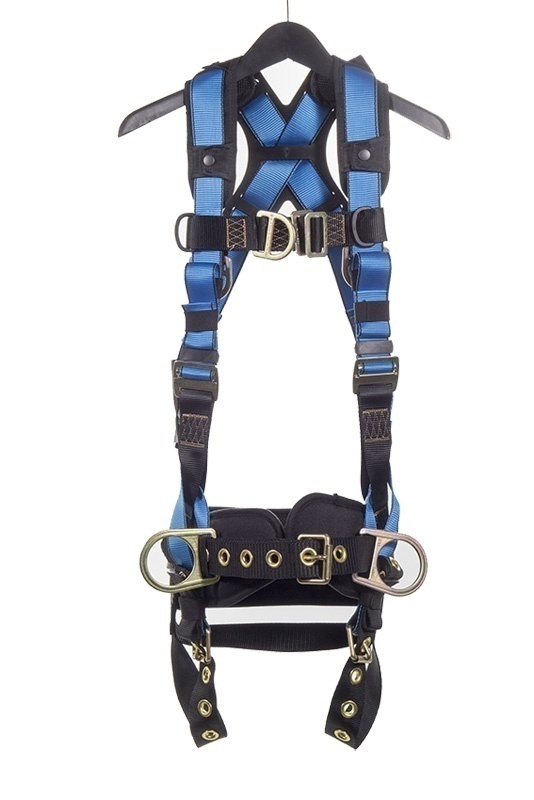

Since soft goods are the most commonly worn out items, harnesses, lanyards, slings, etc., we’ll start with some of the frequent issues that require them to be removed from service. Be sure to check every section of the equipment, not just one or two individual locations. Run ALL of the webbing through your fingers and visually inspect it thoroughly.

- First check a harness or lanyard for its impact indicators to determine if it’s been involved in a fall. Most modern versions of these will have sewn in indicators. If those show a fall has occurred, remove the equipment from service.

- First look for any cuts, knicks, tears, or rips. Different manufacturers have different guidelines for how much of this type of damage is allowable, but better safe than sorry. If you question it, remove it from service.

- Next, any hard spots, burns, chemical, or UV damage. Discoloration from sun or chemical damage may not seem significant but it can weaken the strength of the webbing or cord and reduce the strength.

- Be sure to also inspect any hardware on harnesses or lanyards for rust, deformation, pitting, corrosion, etc.

Inspecting Ropes

For ropes, you’re looking for a lot of the same things as listed above. Be sure to also look for bunching, bird nests, kinking, or unusual twists in the rope as these can also significantly reduce the strength of the rope. Again, run every inch of rope through your hands daily prior to use.

Inspecting Hard Goods

For hard goods like carabiners, shackles, blocks and pulleys you’re looking for traditional metal types of damage. Rust, corrosion, pitting, heat/weld damage, or deformation from overloading or shock impact.

Inspecting SRLs (Self Retracting Lifelines)

Last, let’s look at Self Retracting Lifelines. You’ll want to fully extend the retractable lifeline and ensure that it both feeds out, and back in properly. Then, extend it again and run the entire length of the lifeline through your fingers. For cable lifelines, check for cut or burred wires, bunching, or kinking. For webbing, look for similar things mentioned above for soft goods. Then in a couple different places throughout the length of the lifeline, give it a quick pull to make sure the locking device engages. Also, improper storage can lead to damage to the mechanics of an SRL.Never leave the SRL lanyard paid out and clipped to a lower level. Leaving the spring mechanism inside and SRL under tension for extended periods can damage it and shorten the life of the unit.

Questions or Need More Info?

If you have any questions regarding the above information or need more insight into safety or fall protection in general, reach out to our Gear Experts®! Click here to contact our team, or use the instant chat feature in the lower right hand corner of your browser screen. Also be sure to connect with us on social media to keep up with all of our latest content.